The operation of an Electronic Eyepiece largely relies on its rotor design, accuracy in balancing, and operating speed. Modern models typically come with programmable interfaces that allow users to control acceleration rates, temperature, and run times with great accuracy. Some advanced Electronic Eyepiece incorporate vibration sensing and auto-imbalances for stabilizing high-speed rotation. Additionally, the use of light but strong materials like carbon fiber enhances safety and energy efficiency. This marriage of engineering ingenuity and electronic control combines the Electronic Eyepiece into a reliable partner for research and production environments.

The use of Electronic Eyepiece traverses a number of scientific disciplines. In the manufacture of pharmaceuticals, it cleanses chemical compounds and removes residual unwanted matter. Biochemists employ Electronic Eyepiece in fractionating cells and isolating organelles for subsequent studies. Drink producers utilize it to filter fluids and stabilize their products. The oil and gas industries utilize Electronic Eyepiece to enhance fuel refining and clean products. {Keywords} can also be utilized in environmental analysis, aiding in the detection of pollutants in water and air samples. They are highly accurate and flexible, thus being a fundamental tool within laboratories and the manufacturing industry.

The Electronic Eyepiece technology future lies in automation, digital control, and green engineering integration. Future models will include AI algorithms for speed, balance, and separation efficiency automatic optimization. Energy-efficient motors and recycled materials will reduce environmental impact, following international sustainability goals. Cloud connectivity will allow for remote monitoring and predictive maintenance, with less downtime. In laboratories, Electronic Eyepiece will be completely compatible with smart data systems for real-time reporting and process validation. These innovations promise greater accuracy, reliability, and versatility for research and industrial use.

Well-maintained Electronic Eyepiece assure trouble-free operation and optimize equipment longevity. Users must ensure balanced loading to prevent excessive stress to bearings. Regular cleaning of the rotor, chamber, and seals reduces cross-contamination. Regular lubrication and calibration ensure mechanical accuracy. Logs of maintenance, checklists, and other records facilitate quality control and inspection for compliance. Internal humidity and dust exposure should be reduced. Laboratories use preventive maintenance instructions to guarantee that Electronic Eyepiece delivers constant high performance with little downtime and repair.

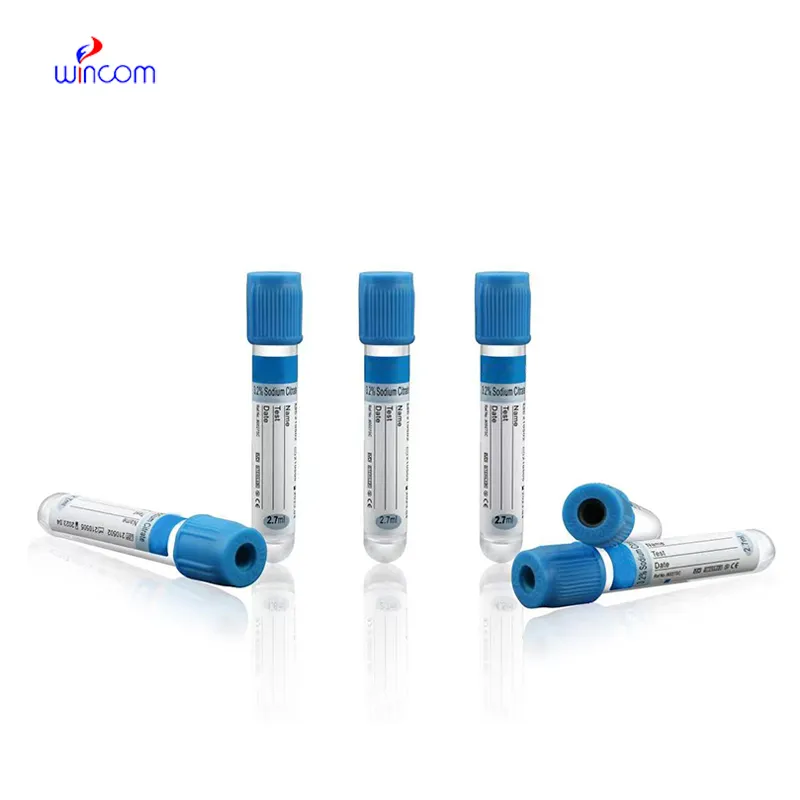

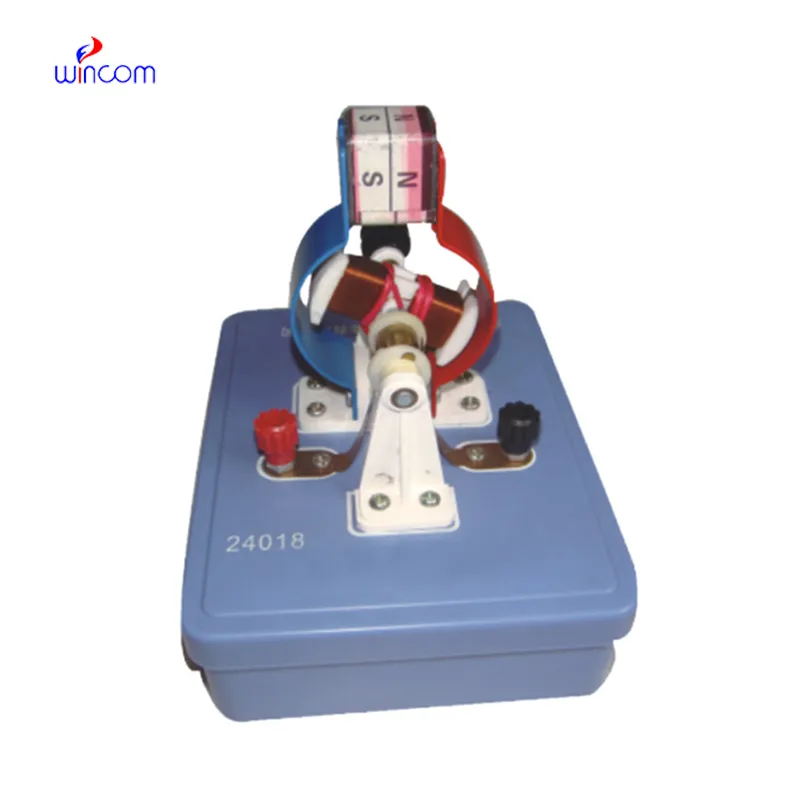

A Electronic Eyepiece operates by inducing centrifugal force through rapid rotation, separating substances according to mass and density. It has a critical use in laboratories, medical testing, and industrial treatment. In medicine, for instance, Electronic Eyepiece facilitate plasma and serum separation for the purpose of diagnosis. In environmental science, they assist in the examination of suspended solids in water samples. Their robust build, combined with programmable functions and safeguarding features, facilitates fine speed control and timing. Electronic Eyepiece continue to evolve to provide faster and more accurate separation procedures in various fields.

Q: What is a centrifuge used for? A: A centrifuge is used to separate mixtures based on density differences by spinning them at high speeds, allowing heavier particles to settle away from lighter ones. Q: How does a centrifuge work? A: A centrifuge operates by generating centrifugal force, pushing denser materials outward while lighter components remain near the center, resulting in effective separation. Q: What are common applications of a centrifuge? A: Centrifuges are used in laboratories, hospitals, and industries for blood testing, chemical analysis, purification, and sample preparation. Q: How often should a centrifuge be calibrated? A: Calibration should be performed at least once a year or whenever performance inconsistencies appear to ensure accuracy and reliability. Q: Can a centrifuge handle biological samples? A: Yes, many centrifuges are designed for biological materials such as blood, plasma, and cell cultures under controlled and sterile conditions.

The water bath performs consistently and maintains a stable temperature even during long experiments. It’s reliable and easy to operate.

The hospital bed is well-designed and very practical. Patients find it comfortable, and nurses appreciate how simple it is to operate.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Hello, I’m interested in your water bath for laboratory applications. Can you confirm the temperat...

We’re currently sourcing an ultrasound scanner for hospital use. Please send product specification...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China