With multi-layer coated optics, the best microscope for laboratory delivers better light transmission and image contrast. Ergonomic design allows for comfortable long-term use. The smooth stage movement and fine focusing system provide sensitive slide control for accurate analysis. The best microscope for laboratory can be used with image capture systems for recording and sharing information, supporting both live observation and digital research workflows in the classroom and lab.

The best microscope for laboratory plays a significant part in modern labs, supporting research as well as applied analysis. In drug analysis, it facilitates critical study of drugs and drug crystallization. The best microscope for laboratory is applied in environmental research to analyze aquatic microbes and assess pollution impacts. Educators use it to enrich laboratory demonstrations of the complexity of plant and animal cells. Engineers apply the best microscope for laboratory to investigate the integrity of material surfaces, supporting product innovation and development across industries.

The best microscope for laboratory will emerge hand in hand with revolutionary breakthroughs in computer science and optics. Future designs will incorporate ultra-sensitive detectors that can measure nanoscale motion in real-time. Through AI-aided enhancement, the best microscope for laboratory will facilitate predictive medicine and materials science analysis. Enhanced portability will allow researchers to employ small units on-site or at remote sites. As further technology emerges, the best microscope for laboratory will provide a critical portal for microanalysis and worldwide science networks.

In the interest of precision and reliability, the best microscope for laboratory should be constantly exposed to cleanliness and maintenance. Switch it off at all times before adjusting or cleaning parts. The lenses may be cleaned with alcohol-free cleaners lightly to avoid scratching. Rotary components such as knobs and stage mechanisms value light lubrication at regular intervals. The best microscope for laboratory must be stored away from direct sunlight and vibration. Professional checking once a year ensures optical alignment is not affected and prevents wear from invisible damage.

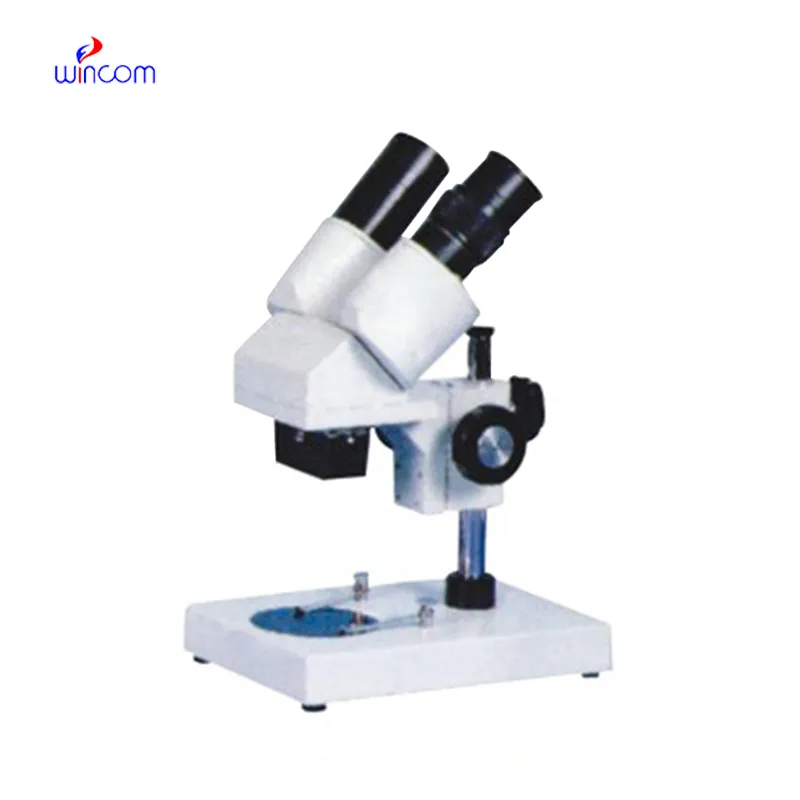

A best microscope for laboratory is a convenient tool that magnifies microscopic materials that are invisible to the naked eye. It allows researchers, scientists, and students to view cells, microorganisms, and sensitive materials with careful attention at microscopic sizes. Modern best microscope for laboratory models combine optical precision with electronic technology to give high-definition images and fine focusing. They are widely applied in biology, medicine, and material sciences for research, study, and instruction. With high-performance lenses and illumination systems, a best microscope for laboratory enhances visualization to enable users to examine texture, shape, and structure at the microscopic level with utmost clarity and accuracy.

Q: How do environmental conditions affect a microscope? A: Excessive heat, moisture, or dust can damage optical and mechanical components, so the microscope should be used in a clean, controlled environment. Q: Can a microscope capture images or videos? A: Many modern microscope models include digital cameras that enable high-resolution image and video capture for documentation or analysis. Q: What training is required to operate a microscope? A: Basic understanding of optics and focusing principles is recommended, though most educational microscopes are designed for simple, intuitive use. Q: Why is regular maintenance important for a microscope? A: Regular maintenance prevents dust buildup, mechanical wear, and misalignment, ensuring consistent performance and image clarity. Q: Can a microscope be used outside the laboratory? A: Portable and handheld microscope models are available for field studies, allowing researchers to observe and analyze samples on site.

We’ve been using this mri machine for several months, and the image clarity is excellent. It’s reliable and easy for our team to operate.

This ultrasound scanner has truly improved our workflow. The image resolution and portability make it a great addition to our clinic.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

I’m looking to purchase several microscopes for a research lab. Please let me know the price list ...

Hello, I’m interested in your centrifuge models for laboratory use. Could you please send me more ...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China