Lightweight yet powerful, the cold press vs centrifugal juicer continues to raise the standard for efficiency of operation. High-performance control algorithms provide instant acceleration and smooth deceleration, protecting delicate samples from stress. Dual cooling systems provide thermal stability in even long runs. Modular design provides easy maintenance and upgrading. Remote diagnostics and system optimization connectivity is available in some models. Along with these advancements, the cold press vs centrifugal juicer becomes a bridge between traditional engineering and modern automation and functions as a pillar of accurate, high-rate separation within labs and factories around the world.

Across different industries, cold press vs centrifugal juicer machinery is a necessity in maintaining process effectiveness. In biotechnology, they are required for cell harvesting and sample preparation prior to downstream analysis. {Keywords} are used by petroleum refineries to separate impurities from lubricants and fuels. Dairy manufacture utilizes their ability to correctly separate cream from milk. Forensic science utilizes cold press vs centrifugal juicer to analyze biological samples with accuracy. Their ability to work with liquids, suspensions, and emulsions of varying densities places them in any setting requiring uniform and repeatable material separation.

{Keywords} in the future will evolve into fully networked instruments in smart laboratories. They will "communicate" with other analytical instruments through built-in digital platforms, making experimental workflows easier. Equipped with self-diagnostic systems, maintenance needs will be identified before any issues arise. Future cold press vs centrifugal juicer models will emphasize energy efficiency and portability without compromising on speed or accuracy, while integration with robotics, AI-driven optimization, and user-friendly interfaces will redefine operations standards. In production and research environments, cold press vs centrifugal juicer will play a key role in achieving higher productivity and sustainable performance.

Maintenance procedure routines protect the performance and safety of cold press vs centrifugal juicer. The rotor needs to be visually inspected before each operation for cracks or corrosion. Mild detergents are needed for cleaning, followed by thorough drying to prevent rust. Calibration verification and vibration monitoring assist in keeping it accurate. The instrument should be set on a level surface to reduce stress on bearings. During storage, cold press vs centrifugal juicer must be kept covered and not plugged to keep electronics safe. Under operator discipline and regular maintenance, laboratories can offer years of trouble-free performance.

The cold press vs centrifugal juicer is an essential instrument in science and engineering. It is able to separate material constituents based on their differences in density by rotating them at very high speeds. In biotechnology, it is used to purify cells, DNA, and enzymes. In chemistry, it purifies liquids and removes impurities from them. cold press vs centrifugal juicer also play a crucial role in medical diagnosis when preparing blood samples. Their mechanical precision and regulation of speed ensure safe use. Constantly enhanced design and electronic monitoring system development enhances efficiency, and cold press vs centrifugal juicer are thus inevitable in numerous modern applications.

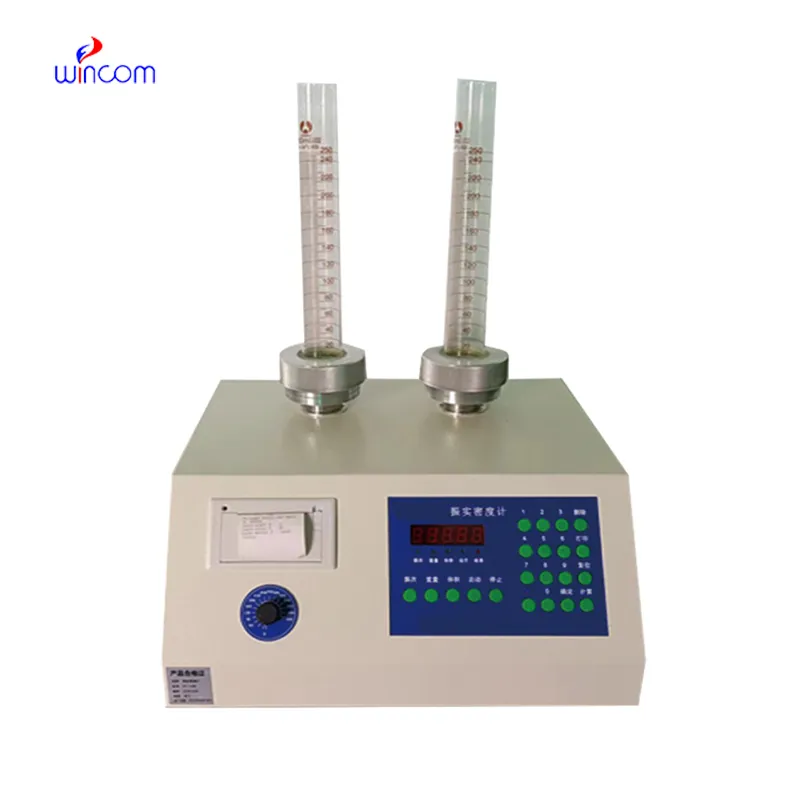

Q: What are the main components of a centrifuge? A: Key components include the rotor, motor, control panel, safety lid, and chamber, each working together to achieve precise separation. Q: How can I verify that a centrifuge is functioning correctly? A: Check that the machine runs smoothly without any unusual vibrations or noises, check the speed accuracy and evaluate the results to ensure consistent separation. Q: Is it safe to open a centrifuge immediately after use? A: No, the device should come to a complete stop before opening to avoid injury or sample disruption. Q: How should a centrifuge be stored when not in use? A:Store it unplugged, covered, and in a dry, dust-free environment to protect internal components from moisture and corrosion. Q: Can centrifuge operation be automated? A: Yes, modern models include programmable controls and digital interfaces that allow automated speed, time, and temperature settings.

I’ve used several microscopes before, but this one stands out for its sturdy design and smooth magnification control.

The water bath performs consistently and maintains a stable temperature even during long experiments. It’s reliable and easy to operate.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

I’m looking to purchase several microscopes for a research lab. Please let me know the price list ...

We’re looking for a reliable centrifuge for clinical testing. Can you share the technical specific...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China